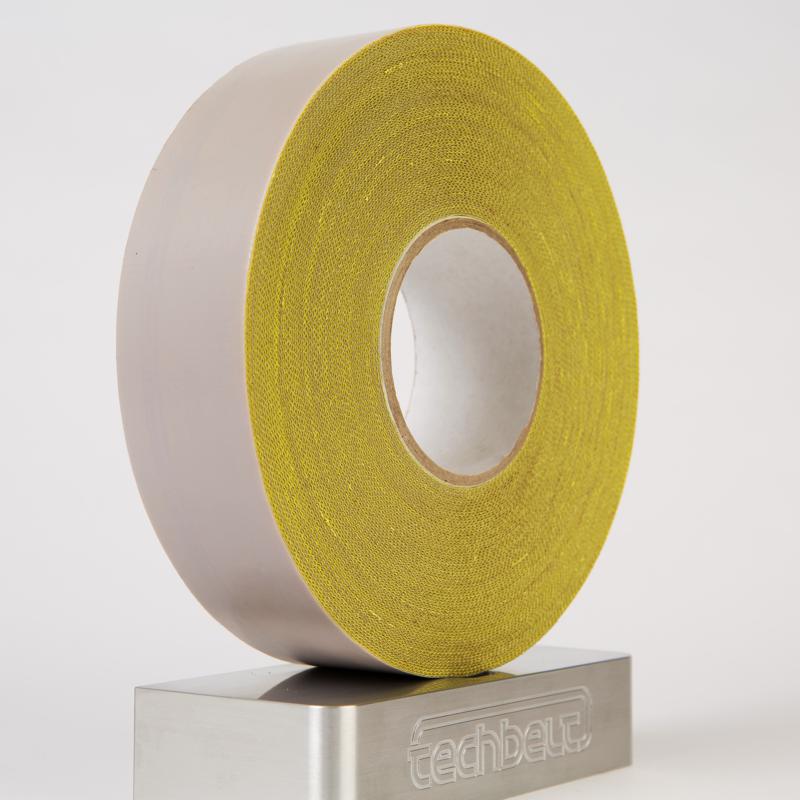

Skived PTFE Adhesive Tape 0.25mm SK10

£29.46

SKU: 620947466655

Skived PTFE materials can be used in many industrial applications due to its unique properties. Its high elongation makes the tape useful in applications that require conformability. The combination of skived PTFE and silicone adhesive offers an effective solution in high temperature and high dielectric applications. Techbelt's skived PTFE tape provides superior wear resistance, low friction and a non-stick surface

| Applications |

|---|

| Areas of use include mechanical applications such as electrical insulation and cable wrapping, bellows and hose liners, gaskets, tank and vessel lining, slide bearings, skid ways, pipe supportand bearing tape. They are also used in many other applications requiring high temperature resistance, low friction and a non-stick surface use on extrusion lines where rubbers, plastics or sticky products may stick to other belt surfaces. |

| Features & Benefits |

|---|

| Skived PTFE tape is not supported by woven fiberglass as other PTFE adhesive tape is and therefore offer excellent conformability in to radiuses and other areas where PTFE coated glass cloth tapes are not suitable. Due to the skived PTFE not being supported by a carrier it has an extended life over standard PTFE glass cloth tapes (known as Teflon tape) and is therefore more suited to environments that may produce a high wear rate. Skived PTFE tapes come in four different grades ranging from 0.08mm to 0.50mm thick. all have a high temperature resistant, silicone adhesive backing. The adhesive is pressure sensitive and will adhere to hot metal surfaces. They are supplied in slit roll form ranging from 10mm to 1000mm wide an 30mtr coils. We also sell these products by the square meter. Lead time is generally same day dispatch from order. |

| Material Properties | |

|---|---|

| • Extremes of heat and cold resistance -73°C to +260°C | • Chemical inertness affected by a few rare substances at high temperatures |

| • High release from sticky materials 'Non-stick' | • Easy cleaning (nothing bonds permanently) |

| • Low friction co-efficient: 0.04 - 0.10 depending on the load and surface speed | • Chemical corrosion and moisture resistance |

| • Ultra violet, infra-red, micro-wave, radio frequency resistance | • Non combustible - self extinguishing |

| • Low thermal expansion < 5% | • Food approval (USFDA) |

| • Lightweight and energy efficient for economical operation | |

| Specification | |||

|---|---|---|---|

| • Weight without adhesive: | ± 5% 573g/m2 | • Adhesive type: | Silicone PSA |

| • Weight including liner: | 720g/m2 | • Adhesion: | 5.5 N/cm |

| • Thickness without adhesive: | 0.25mm | • Adhesive temperature resistance: | -73 to +240°C |

| • Thickness without liner: | 0.315mm | • Elongation: | 300% |

| • Surface texture: | Smooth non-stick | • Dielectric strength: | 15600V |

| Important Storage / Shelf Life and Application Information |

|---|

| • Storage: We strongly recommend that Techbelt silicone PSA tapes are stored at room temperature conditions of 21⁰C (70⁰F) and 50% relative humidity and should be protected from direct sunlight and moisture. |

| • Shelf Life: If stored correctly, these products retain their performance and properties for 6 months from date of manufacture. |

| • Surfaces: The surfaces of the materials to be bonded must be dry and clean. Condensation of moisture on surfaces to be bonded (e. g. when carrying cold objects into a warmer room) must be avoided. The materials to be bonded must be free from dust, grease, oil and separating agents and cleaned if necessary. |

| • Cleaning: For cleaning the surfaces only use a clean cloth and a solvent that is compatible with the materials, e. g. benzines, alcohol, esters or ketones. |